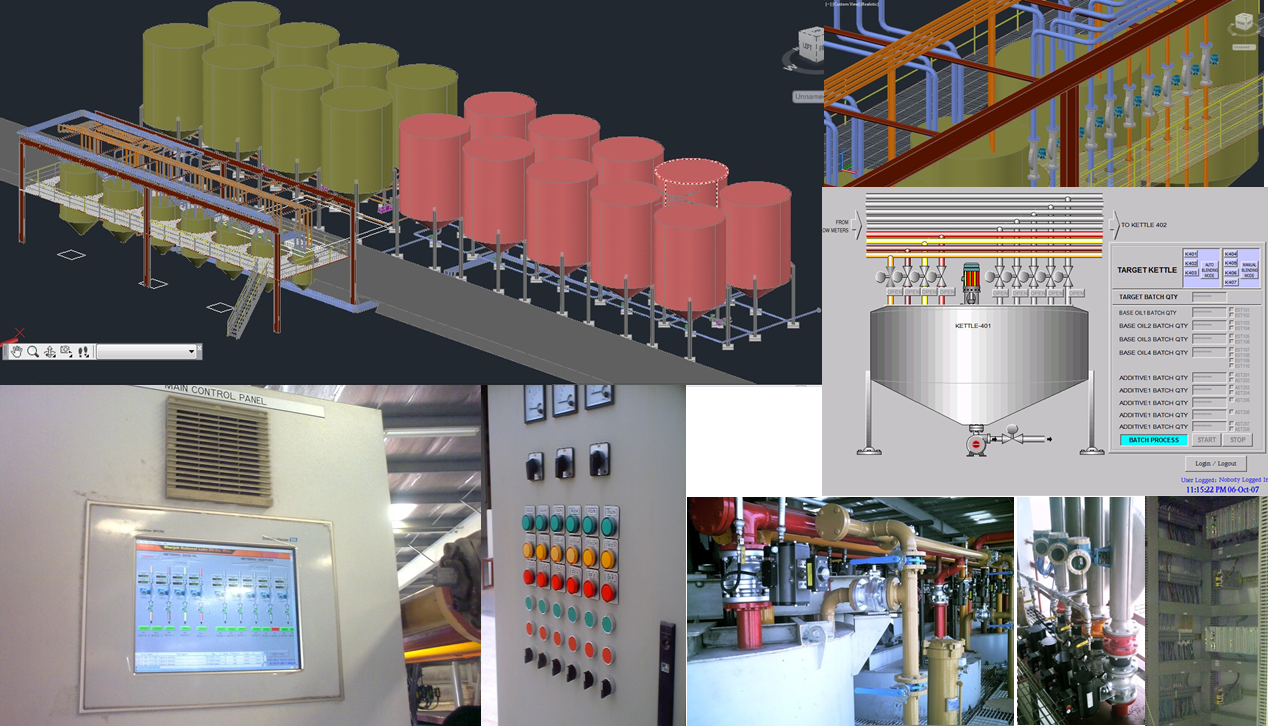

Lube Oil Blending Control Monitoring System:

Designed, integrated & commissioned in the year 2007 and annual maintenance till date is carried out by Descon Automation Control System LLC.

Application description: Control System for Lube Oil Blending Operations.

- Variety of Base Oil and Additives are measured by Promass and transferred to blending kettles while the quantity verification and blending operation are monitored and controlled by E+H ControlCare hardware and PView Visualization. For management access WebHMI also enabled.

- Base Oil and Additives are taken from different tanks which have Level Switches to protect from dry running and overfill. Tank Farm is controlled from a Field Controller Panel via HSE (High Speed Ethernet).

- There are 7 (seven) Kettles for blending operations. These would have necessary heaters and temperature transmitters to monitor the temperature. A blending mechanism driven by suitable motors which are controlled by our offered system. After blending the raw materials until a pre determined time and/or a temperature set point the process will be stopped and the product will be transferred tot holding tanks.

Descon Automation Control System LLC Scope:

- Controller Panel engineering and assembly.

- Cables: Supply and installation of System / power cables. Installation of panels and fittings as required.

- Field cables interconnection: Supply and installation of junction boxes.

Strengths:

Strengths:

- Installed base with mass flow meters with present plant facilities.

- Confidence level at customer end through the technical support provided by Descon Automation Control System LLC.

- Complete Project Involvement from conceptual design to implementation of Lube Oil Blending Plant – Piping and Instrumentation.

- Project Execution Team having high caliber and dedication to the organization.